Rotary tables play a pivotal role in helping to ensure the effective and precise machining of parts. So, being proactive by performing regular maintenance on rotary tables is essential to help ensure their continued reliability, accuracy, and longevity. Neglecting maintenance can lead to decreased performance, increased downtime, and potentially costly repairs.

Proactive On-Site Rotary Table Inspection

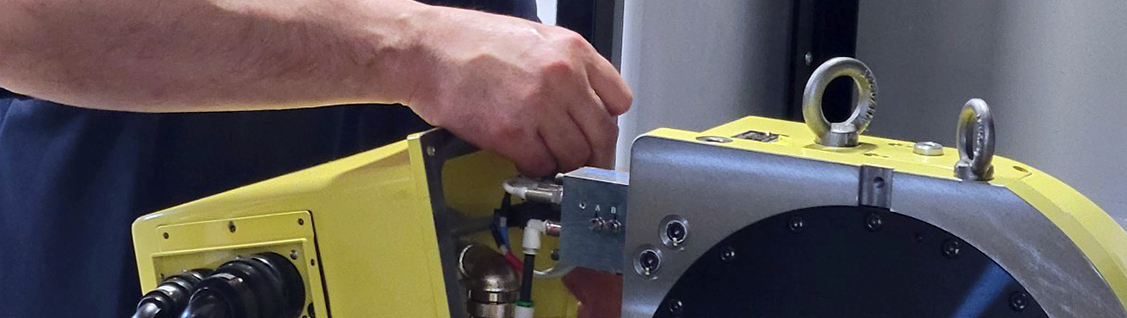

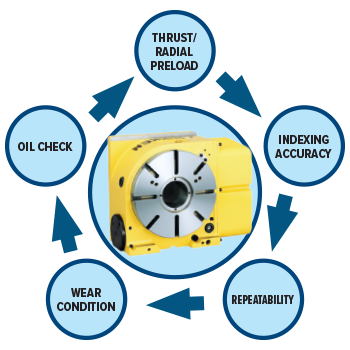

Lyndex-Nikken offers a Check-Up Program that provides proactive on-site inspection of your Nikken rotary tables to help provide early detection of failure points in the manufacturing process. A Lyndex-Nikken technician will come to your facility and evaluate your Nikken rotary tables backlash, braking system, and overall condition. We will provide you the test data of your Nikken rotary tables, review the data with you, and give recommendations to help eliminate downtime.

By being proactive, here is how you can benefit:

- Decreased Downtime: Our scheduled maintenance checks and diagnostics help identify potential issues before they become major problems, reducing the risk of unexpected downtime.

- Consistent Part Quality: A properly maintained rotary table contributes to consistent part quality and maintaining the desired tolerances in the finished parts - essential for meeting customer specifications and maintaining a reliable reputation.

- Increased Productivity: Regular maintenance prevents costly production interruptions, enabling you to meet deadlines and fulfill customer orders without delays.

- Extended Equipment Lifespan: Proper care and maintenance can significantly extend the life of your CNC automation equipment, providing a higher return on investment over the long term.

- Cost Savings: By addressing minor wear and tear early on, you can avoid last minute expensive repairs and replacements down the line.

Get started on setting yourself up for success, contact us today!